A highly collaborative effort that draws on the leadership and expertise of faculty, researchers, students, administrators, and staff, the EHS Management System shapes how all members of the MIT community view their environmental, health, and safety responsibilities; carry out MIT’s comprehensive and integrated environmental commitment in their day-to-day activities; and assess MIT’s performance against our goals.

The management system has been designed to address three interdependent goals:

- Supporting the independence of research and teaching while continuously improving MIT’s performance in meeting and exceeding regulatory requirements and achieving high standards for environmental sustainability and health and safety.

- Reflecting and facilitating MIT’s broad commitment to environmental excellence and stewardship.

- Supporting MIT’s comprehensive and integrated approach to managing EHS performance.

Please take a moment to familiarize yourself with the contents of the EHS – MS Pamphlet.

- Access EHS-MS Applications in Atlas – certificates required. In the left menu, select “Full Catalog” and search on “EHS”

Step by step checklist for new Faculty(PI) overseeing research labs:

| Task | Link |

| Get to know your Department, Lab or Center’s EHS Coordinator and Lead Contact. Refer to the table linked at right for name and contact information. | |

| Complete an EHS Training Needs Profile in Atlas to identify your required training and assure all personnel working in the lab complete training profile/requirements (need MIT ID and Kerberos name and certificates). | |

| If renovations are being done to prepare a space for your research needs, involve EHS to assure the space meets your EHS needs. Review the information and complete the EHS laboratory assessment form. | |

| Designate a person to be the lab EHS Rep. (Note: Sometimes new PIs serve as the EHS Rep until their lab is more established.) | |

| Once the lab is operational and an EHS Rep is chosen, contact EHS Coordinator to register space and obtain emergency green cards. |

|

| Review the Chemical Hygiene Plan for your DLC and your responsibilities listed in this plan. Ask your EHS Coordinator for a copy of the plan. | |

| Establish a Chemical Inventory using one of the tools provided. | |

| Biological agents. For most research with biological agents, you will need to complete a biological research registration for review by the Committee on Assessment of Biohazards (CAB). Contact the Biosafety Program at 2-EHSS for assistance. |

|

| Human materials. For work with human materials, you will need to complete an exposure control plan. | |

| Radioactive materials. For work with radioactive materials, you will need a Radioactive Materials Use Authorization. Contact the Radiation Protection Program at 2-3477. |

|

| Obtain and enforce use of personal protective equipment for lab research. In addition to information linked at right, you will find useful information on PPE requirements and selection in your department’s Chemical Hygiene Plan. | |

| Work with your EHS Coordinator to establish hazardous waste management procedures in your lab. | |

| Establish procedures for conducting weekly inspections in the lab, referred to as Level I Inspections, and addressing inspection findings. |

|

EHS-MS Manual

This Manual is designed to serve as a comprehensive guide to the EHS Management System and all of its related components. It provides a detailed overview of the Management System’s design and approach, and a summary discussion on all of the organizational components of the Management System. The Manual is an excellent source for obtaining a high-level and comprehensive perspective and understanding of the Institute’s EHS requirements and the tools available to meet those requirements. All students, faculty, and staff should read the Manual to better assist in contributing to sound EHS practices.

The Manual is organized around the seven central components of the Management System:

- MIT’s EHS Policy and Objectives (Policy and Objectives)

- The Roles and Responsibilities for Implementing the Management System (Roles and Responsibilities)

- How MIT Plans for Continual EHS Improvement (Getting Started)

- The EHS Training Requirements and Delivery Systems (Training)

- EHS Services and Data Management (Operations)

- Inspections and Audits

- EHS Incident and Non-Compliance Investigations (Incident and Investigations), and

- EHS Communications (Communications)

The Manual can be used in two ways. Reading the Manual in its entirety will provide the most integrated and comprehensive perspective on the purpose, approach, and tools MIT has deployed to help the MIT community meet and surpass its EHS obligations. Also, the Manual can be used as a central reference source to access information on specific components of the Management System as needed.

The Manual provides links to essential procedures and tools that support the day-to-day demands of implementing the Management System and carrying out your EHS activities.

Can’t find what you are looking for or have questions about the EHS Management System? Please contact the EHS Office at 617-452-3477 or send us an e-mail at environment@mit.edu.

MIT has a comprehensive and integrated Environment, Health, and Safety Management System (EHS-MS) that is sustainable for the long term within our academic research setting. A highly collaborative effort that draws on the leadership and expertise of faculty, researchers, students, administrators, and staff, the EHS Management System helps to shape how all members of the MIT community view their environment, health, and safety responsibilities, carry out MIT’s comprehensive and integrated environmental commitment in their day-to-day activities, and assess MIT’s performance against our goals.

A Systems Approach

Through the well-defined and structured EHS Management System that is embedded in the daily activities of the Institute, MIT has infrastructure that ensures long-term success and sustainability in meeting and surpassing its environment, health and safety obligations. Each component of the EHS Management System is designed to work interdependently in an integrated fashion that continually reinforces the common objective of improving EHS performance.

To ensure the organizational sustainability of the EHS Management System, all components of the Management System, such as Policy and Objectives, Planning, Training, and Inspections are designed and established as formal systems, integrated into on-going academic and facilities operations, and evaluated as needed to identify areas for continual improvement. It is these core systematic components that act both independently and cooperatively to form the backbone of the EHS Management System.

One of the central principles of this system and of our EHS Policy is the commitment to reflect our long held values of excellence not only in our research and teaching, but also in our operations. This Management System provides improved institutional capacity and accountability for achieving and maintaining compliance with MIT’s high standards for EHS performance, and federal, state, and local EHS regulations in MIT’s departments, laboratories, and centers (DLCs), while simultaneously retaining the independence of research and teaching. The EHS-MS also creates a more sustainable campus by encouraging the incorporation of positive initiatives into activities, such as reducing wastes and toxic materials, preventing pollution, fostering innovation and entrepreneurship, and conserving and reusing resources. One of the defining features of MIT’s EHS-MS is to integrate regulatory compliance with positive initiatives and educational programs in a decentralized academic research setting.

The EHS-MS operates in tandem with MIT’s existing policies and procedures. It includes and implements MIT’s EHS Policy, which has the full authorization, approval and support of the MIT Academic Council, our highest policy-making council convened by the President and comprising the Institute’s senior officers. MIT senior management has established and is committed to maintaining the EHS-MS.

This Manual describes the elements of MIT’s EHS-MS; the established policies and procedures that MIT follows to meet applicable environment, health and safety performance and legal requirements; and policies and procedures to comply with other requirements to which MIT voluntarily subscribes.

MIT’s comprehensive EHS Policy describes and communicates the Institute’s commitment to excellence in environment, health and safety stewardship. In particular, MIT’s EHS policy commits the Institute to:

- Minimizing adverse EHS impacts,

- Achieving and maintaining compliance with EHS regulations,

- Achieving a high standard for accountability for EHS stewardship,

- Providing educational opportunities, and

- Continually improving EHS performance

The EHS Working Committee and the Institute Council on Environment, Health and Safety (co-chaired by the Vice President for Research and Associate Provost and the Managing Director, EHS Programs, and comprising senior faculty and administrators) developed and endorsed the policy. The policy was then presented to the Academic Council, which is chaired by the Institute President and serves as the President’s cabinet for Institute-wide policy-making. Following approval by the Academic Council, the policy was adopted by MIT on December 11, 2001 and reaffirmed on November 2, 2007.

The EHS Policy is communicated to the MIT community through a variety of means as described more fully in the EHS Communications Plan and outlined in Section 8, Communications. The EHS Policy is provided to students, faculty, researchers, and staff during many orientation and training opportunities.

The EHS Policy is reviewed and modifications to the policy are considered as needed or as part of the overall EHS-MS management review process as described in Section 6.1, Inspections.

MIT is committed to being at the forefront of large academic research institutions in measuring and continuously improving environment, health and safety performance. One way that MIT improves its EHS performance is through the implementation of action plans to meet specified objectives and targets. The objectives and targets are developed through a variety of processes as described in Section 3.9, Establishing and Updating Targets, Objectives, and Action Plans and progress is monitored on an ongoing basis.

MIT’s Environment, Health and Safety Management System is responsive to the overall structure and culture that exist in the MIT community.

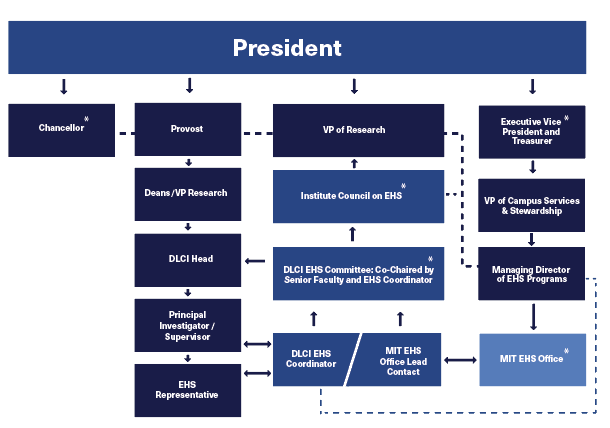

The EHS-MS Governance Chart (Figure 1) provides a framework that fosters communication and effective working relations among Departments, Laboratories, and Centers (DLCs), the Environment, Health and Safety (EHS) Office and MIT’s senior officers (including the President, Provost, Chancellor, Executive Vice President and Treasurer, Vice Presidents, and Deans).

Figure 1: EHS-MS Governance Chart

2.1.1 Senior Officers

MIT’s Senior Officers include the President, Provost, Chancellor, Executive Vice President, Vice Presidents, and Deans. This executive staff provides resources, including human resources, specialized skills, technology, and financial resources, essential to the implementation and control of the EHS-MS.

2.1.2 Councils and Committees

The governance of the EHS-MS is designed as a framework to incorporate multi-disciplinary relationships to assure that EHS issues are addressed in a comprehensive and integrated fashion. These relationships are established through various committees whose functions are summarized below:

- Council on Environment, Health and Safety

- Animal Care

- Assessment of Biohazards and Embryonic Stem Cell Research Oversight

- Radiation Protection

- Reactor Safeguard

- Toxic Chemicals

- Use of Humans as Experimental Subjects

Institute Council on Environment, Health and Safety

The Institute Council on Environment, Health and Safety (ICEHS) reports to the President and is responsible for coordinating policy development, the assessment of procedures of the Institute Committees concerned with specific areas of environment, health and safety, and overseeing the implementation and effectiveness of the EHS-MS. The Council serves as a forum in which shared concerns of these Committees are coordinated and where issues of individual Committees are resolved. The Council is also responsible for identifying new environment, health and safety issues that emerge as new activities are undertaken and new technologies evolve. In instances where such new activities do not fall within the purview of an existing committee, the Council may expand the area of concern of an existing committee or recommend the creation of a new committee.

The Council’s membership includes chairs/heads of these Institute Committees and Administrative Units:

- Vice President for Research and Associate Provost, Chair

- Managing Director, Environmental, Health and Safety Programs

- Director, Environment, Health and Safety Office (ex-officio)

- Chair, Committee on Animal Care

- Chair, Committee on Assessment of Biohazards and Human Embryonic Stem Cell Research Oversight

- Chair, Committee on the Use of Humans as Experimental Subjects

- Chair, Committee on Radiation Protection

- Chair, Committee on Reactor Safeguard

- Chair, Committee on Toxic Chemicals

- Service Administrators from Department of Facilities and Lincoln Laboratory

Committee on Animal Care

MIT’s Committee on Animal Care (CAC) reviews and approves all experiments involving animals to ensure that MIT researchers working with animals comply with federal, state, local and institutional regulations on animal care. To that end, the CAC inspects animals, animal facilities and laboratories, and reviews all research and teaching exercises that involve animals before approving experiments to be performed.

Committee on Assessment of Biohazards and Human Embryonic Stem Cell Research Oversight

The Committee on Assessment of Biohazards and Human Embryonic Stem Cell Research Oversight (CAB/ESCRO) reviews and approves research involving potential health and safety problems associated with biological research and Dual Use Research of Concern (DURC)

Committee on Radiation Protection

The Committee on Radiation Protection is responsible for developing and monitoring the Institute’s radiation protection program. The Committee is also responsible for assuring the Institute’s compliance with radiation protection regulations promulgated by state, federal, and local agencies.

Committee on Reactor Safeguard

The Committee on Reactor Safeguard is responsible for matters of nuclear safety related to the MIT Research Reactor, including the safety of personnel on and off site. The Committee reviews and approves all new operating plans and policies, including significant modifications, and all new experiments involving significant changes in procedure prior to implementation. The Committee verifies that nuclear reactor operation is consistent with MIT policy, rules, approved operating procedures, and license provisions.

Committee on Toxic Chemicals

The Committee on Toxic Chemicals (CTC) is responsible for reviewing current practices with regard to the effects of toxic chemicals, including carcinogens. The Committee is also responsible for developing policies necessary to control the risks and exposure to personnel working with such agents, and for ensuring compliance with rules and regulations.

Committee on the Use of Humans as Experimental Subjects

The Committee on the Use of Humans as Experimental Subjects (COUHES) reviews and approves all research involving human subjects that is performed under the auspices of MIT in accordance with Federal regulations and MIT policy. Types of research that must be reviewed by the Committee include investigation of new drugs and medical, radiological, engineering, physiological, behavioral, sociological, and nutritional studies.

The Departments, Laboratories and Centers (DLCs) are the primary organizations that implement and maintain sound EHS practices and ensure EHS compliance.

The following sections explain roles and responsibilities for EHS activities within DLCs. A person in a specific role is responsible for certain EHS activities whether by performing those activities or overseeing other(s) in performing those activities. This is intended to provide flexibility to each DLC and the central EHS Office to operate in the most efficient and effective manner while defining certain functions that must be performed.

The EHS-MS Governance Framework depicts the working relationships between the DLCs and the EHS roles described below.

2.2.1 Department Heads/Directors, Principal Investigators and Supervisors

DLC Head/Director – has the primary responsibility and authority of directing and managing the DLC and therefore has final responsibility for assuring sound EHS practices and compliance within the DLC. The DLC Head/ Director is responsible for appointing the DLC EHS Coordinator and providing support to the Coordinator. The DLC Head/Director is ultimately responsible for enforcing consequences arising from poor EHS performance, moderately serious and/or very serious incidents. The DLC’s EHS performance evaluation is included in the annual report to the President of MIT and/or to the relevant Dean’s Office. Finally, the DLC Head/Director is responsible for ensuring contractors and visitors to the DLC, or anyone acting on behalf of the DLC, are informed of MIT EHS requirements and that the EHS Office is contacted, as needed, for any EHS concerns arising from the contractor/visitor activities.

Principal Investigator (PI)/Supervisor – is responsible for compliance with EHS regulations and good practices in his or her laboratory or non-research facility and plays a critical role in the function of the EHS-MS. The PI/Supervisor has the responsibility to appoint an EHS Representative to assist in meeting his or her EHS responsibilities. If an EHS Representative is not appointed, the PI/Supervisor also acts as the EHS Representative. In administrative DLCs, such as the Department of Facilities and Division of Student Life, the Supervisor acts as the EHS Representative. In addition, the PI/Supervisor has the authority and is responsible for:

- insuring that assigned spaces where hazardous and/or regulated materials or equipment are used and stored are registered in the PI/Space Registration and updated when new hazards are introduced or processes change;

- attending all required EHS training and assuring that all laboratory or facility personnel under his or her supervision are trained;

- ensuring hazard assessments are made, procedures established, and engineering controls and personal protective equipment are provided for safe work environment;

- assuring that EHS inspections are conducted as required, and that any problems identified are addressed;

- reporting injuries and incidents, such as spills, using the online EHS Supervisor’s Injury Report, and investigating them to determine if action is needed to prevent similar injuries or incidents and contacting EHS Office as needed for assistance;

- ensuring emergency preparedness and response procedures are identified and followed.

2.2.2 EHS Coordinators and Representatives

EHS Coordinator – receives authority from and acts on behalf of the DLC Head/Director to carry out EHS programs. The EHS Coordinator provides operational day-to-day oversight of the DLC’s EHS-MS requirements. Please refer to EHS Team List for your DLC EHS Coordinator. In addition, the EHS Coordinator supports the EHS Representatives and PIs/Supervisors by providing additional authority and resources to address EHS issues, including regulatory deficiencies, training needs, and other EHS-MS needs. Specific duties of the EHS Coordinator include but are not limited to the following:

- to serve as Co-Chair and a member of the DLC EHS Committee, and to retain records of EHS Committee meeting;

- to convene a meeting of the DLC EHS Representatives and EHS Office Lead Contact at least annually and retain a record of the meeting(s). An EHS Coordinator who prefers to meet one-on-one, or with smaller groups of EHS Representatives instead of convening the entire group must work with the EHS Office to determine a sustainable strategy for including the EHS Office Lead Contact in these meetings.

- to work with PI/Supervisors to register spaces and associated hazards in the PI/Space Registration;

- to conduct inspections of DLC spaces, as required by EHS-MS, and to provide follow-up and assistance as needed to address inspection findings;

- to assist with emergency response;

- to serve as DLC Emergency Preparedness Coordinator (EPC) when no other EPC has been assigned;

- to review and update the DLC Chemical Hygiene Plan annually and serve as the DLC Chemical Hygiene Officer when needed;

- to serve as a contact for DLC EHS concerns, facilitating communication between DLC Personnel and EHS Office staff to address those concerns.

EHS Representative – reports to and assists the PI/Supervisor in identifying and addressing EHS issues. The EHS Representative initiates actions where appropriate, and brings issues to the EHS Coordinator and PI/Supervisor when his or her authority is required to address an EHS issue. In administrative DLCs, such as the Department of Facilities and Division of Student Life, the Supervisor acts as the EHS Representative. Specific duties of the EHS Rep include but are not limited to:

- assuring new personnel in the lab/work area complete their EHS Training Needs and complete required training prior to working with hazardous materials or performing hazardous tasks;

- assisting the EHS Coordinator in maintaining PI/Space registration data (as outlined in Section 3.2) and emergency contact information.

- conducting weekly inspections in registered spaces and communicating the findings to the PI/Supervisor or the EHS Coordinator.

DLC EHS Committee – is a forum for single or multiple DLCs to review and discuss EHS regulations and practices and establish strategies to implement them in the DLC. This Committee is co-chaired by the EHS Coordinator and a senior faculty member, researcher or supervisor from within the DLC. The EHS Office Lead Contact and/or other EHS Team Members also participate in the committee in an advisory role. Each Committee meets annually at a minimum and keeps records of the meetings. In a DLC where the DLC Head / Director wishes to be actively involved with the DLC EHS Committee and act as the committee chair, the DLC’s EHS Committee could consist of the DLC Head, DLC EHS Coordinator and EHS Lead Contact. Their meeting(s) that take place during the course of inspections could satisfy the requirement for an annual committee meeting if a record is kept. In addition, the DLC EHS Committee provides guidance to the DLC EHS Coordinator and reviews operations within the DLC that may impact compliance with EHS requirements, EHS incidents and EHS-MS documents. DLC Heads/Directors have discretion to determine the extent to which they employ their DLC Committee to oversee EHS performance in their DLC.

2.2.3 Employees and Students

Employees and students are responsible for compliance with EHS regulations and requirements in their research, classroom work areas and residences. Specific responsibilities include:

- completing the EHS Training Needs Identification and taking required training prior to commencing their regulated or hazardous work and duties. Updating the training as required;

- following established procedures for working safely in the lab or work area;

- using and maintaining personal protective equipment if provided;

- reporting work-related injuries or illnesses, incidents such as spills, or near misses to PI/supervisor as soon as possible.

2.2.4 Contractors and Visitors

Contractors and visitors are responsible for compliance with EHS regulations and requirements, as appropriate, based on their work or activities at MIT. These requirements may include taking EHS training offered by MIT. (For more information, see EHS and Security Information for Visitor/Contractor.) DLCs are responsible for assuring their contractors and visitors are informed of MIT EHS requirements and that the EHS Office is contacted, as needed, about any EHS concerns introduced by the contractor/visitor and their activities at MIT.

MIT’s commitment to an effective EHS-MS is demonstrated through our documented policies and procedures that clearly define roles and responsibilities.

EHS Headquarters Office (EHO) – is responsible for participating in the establishment of MIT’s EHS vision and leadership and coordinating collaborative EHS initiatives among all constituents of the MIT community. The EHO, with support from EHS Office, reviews DLC appointments of EHS Coordinators and reports on EHS matters to the Institute Council on EHS. EHO serves as MIT’s senior administrative office for EHS affairs and has access to the senior management at MIT, including offices of the President, Provost, Chancellor, and Executive Vice President. EHO represents the administration of the EHS Management System, including the EHS Office, to Institute leadership for matters of policy, budget, organization, and major process and technology programs.

EHS Office – provides technical expertise and EHS advisory services to the MIT community that collaborate and support regulatory compliance and improved EHS performance at the DLC level. EHS Office is responsible for tactical and operational implementation of the EHS-MS. This includes providing interim support for DLC EHS-MS operations to those DLCs working with potential hazards or regulated activities that have an open position for the DLC EHS Coordinator. It also includes monitoring DLCs that do not have spaces identified in PI/Space Registration in order to add them to the system if they do begin to work with potential hazards or regulated activities. The EHS Office is responsible for implementing the programs identified in the overall vision and strategy set by the EHO, and to promote day-to-day good practices, compliance related activities, and initiatives that advance MIT’s commitment to environmental, sustainability, and health and safety excellence. These services are designed to fully support all aspects of the Institute’s EHS-MS and enable continuous improvement of the system. The EHS Office consists of five technical programs and ten functional areas, which are:

Programs

- Biosafety

- Environmental Management

- Industrial Hygiene

- Radiation Protection, and

- Occupational and Construction Safety

Service Teams

- Organization

- Inspection/Audit

- Training

- Emergency Response

- Laboratory-Facility Design

- Technology

- Communication

- Regulated Waste

- Safe and Sustainable Labs

- Shipping Hazardous Materials

Common EHS Services for All DLCs

- Emergency Preparedness

- Ergonomics

- Field Safety

- Fire Protection

- Indoor Air Quality

- Injury/Incident Reporting

In addition, ongoing EHS staff development is a key component of the system and is monitored by the Director of the EHS Office and the Associate Directors of the five EHS Programs. EHS Office services are further described in Section 5.2, EHS Office Programs, Services and Service Teams. EHS-MS is implemented and maintained by the Director of the EHS Office.

EHS Office Lead Contact – is a representative from within the EHS Office who provides EHS expertise to an assigned DLC. The EHS Office Lead Contact partners with the DLC EHS Coordinator (or is equivalent to a Coordinator for DLCs without Coordinators – see 2.2.2) in order to deliver programs that comply with regulations and meet EHS requirements applicable to that particular DLC. The EHS Office Lead Contact is also a member of the DLC EHS Committee. The EHS Office Lead Contact is supported by a team of subject matter experts from the EHS Office’s areas of technical and functional expertise.

DLC EHS Team – is a group of EHS professionals representing each of the five EHS Office Programs that provide expertise and consultation in EHS matters to their assigned DLC. The EHS Office Lead Contact is the primary contact on the EHS Team for the DLC.

See the DLC Coordinator Contacts page for a list of DLC Team Members.

MIT has established incentives and consequences to support EHS performance.

2.4.1 Accountability and Responsibilities

MIT’s faculty, researchers, staff, and students are all individually responsible for implementing the EHS Management System, and for complying with MIT’s high EHS standards as well as federal, state, and local EHS regulations, and other requirements. In addition, faculty, researchers, students and staff are expected to employ best feasible management practices to ensure a safe, healthy and environmentally sustainable campus.

The responsibility for satisfying MIT’s EHS Requirements is designed to flow through the supervisory chain:

- From individual researcher, student or staff member;

- To Principal Investigators or other Supervisors, who are responsible for compliance with EHS Requirements by members of their labs or groups;

- To DLC Heads/Directors, who are responsible for their DLC’s performance;

- To the Vice Presidents and Deans, who are responsible for their School’s performance

- To the EHS Council and other Committees, responsible for overall Institute performance and oversight, in close consultation with the EHS Office, and

- To the Senior Officers of the Institute

2.4.2 Incentive Programs

MIT’s Recognition Program provides three different opportunities for recognizing excellent performance of academic and administrative employees in a particular area or a project to supplement the Periodic Performance Review process.

Appreciation awards are small, such as thank-you notes, lunches and other small prizes, and given at the time of a specific achievement to provide immediate and spontaneous recognition of an exceptional contribution by an individual and/or team.

Infinite Mile awards are larger financial or non-financial awards that recognize excellent contributions to the objectives of each strategic area within the Institute. The Institute has been organized into a number of clustered groups to enable each area to customize and implement an Infinite Mile Awards program that reflects the work, values and/or behaviors specific to that area. DLCs may include EHS performance as one of the criteria for determining these awards.

The MIT Excellence Awards is a formal, Institute-wide annual ceremony administered by central HR. The MIT Excellence Awards + Collier Medal acknowledge excellent contributions to the values and goals of MIT’s mission statement. Award winners are nominated for one of seven categories, any one of which can recognize EHS contributions.

In addition, EHS Office, supported by the Institute, recognizes DLCs for their excellent performance in EHS Training and Level II Inspection metrics annually with the EHS Excellence Awards. DLCs are evaluated and categorized based on the number of trainees in a DLC: small (1-50), medium (51-250), and large (greater than or equal 251). To be considered for the award, training for core EHS courses and inspection metrics for the entire DLC must be above 90% for the previous year. The award is given to the highest performing DLC for each category.

For past recipients of the awards mentioned, visit EHS Recognition Program.

2.4.3 Consequences for Poor Performance

MIT has established an organizational structure with designated staff such as DLC EHS Coordinators and EHS Office Lead Contact to support DLCs in complying with EHS regulations and good EHS practices.

Members of the MIT community, including faculty members, researchers, staff, and students, are responsible for complying with MIT’s high EHS standards as well as federal, state, and local EHS regulations and good EHS practices. In the event any member of the MIT community fails to fulfill his or her responsibility, appropriate consequences, as described in the Corrective Actions and Consequences Framework / Guideline (PDF) (certificate login required) document, apply. Consequences in all departments, labs or centers will be applied in a way that is consistent with MIT’s human resources or academic disciplinary procedures. Semiannually, EHS coordinators receive an email with performance metrics attached if either or both of the following two criteria were met:

- <80% completion of Level II Inspections reported on the last inspection round

- <80% EHS Training completion in one or more core EHS courses.

If improvement in performance is not noted in the next round this is escalated to either the DLC Head or the relevant Dean’s Office.

There are a number of environmental, health and safety (EHS) issues to consider in establishing a new laboratory or workspace at MIT. The following sections describe EHS Rules and regulations and MIT’s requirements and provide guidance on meeting these requirements while getting started doing research or work at MIT. “MIT Quick Guide for PIs” from the MIT Research Administration Services (RAS) includes some, but not all, EHS requirements.

3.1.1 Identifying and Interpreting EHS Rules and Regulations

MIT’s Environment, Health & Safety (EHS) Office manages environment, health, and safety programs and supports EHS performance including sustainability, good practices, and legal compliance throughout the MIT community. The EHS Office’s Compliance Management Plan identifies and interprets the laws, regulations, and other requirements that apply to MIT facilities and operations; describes the requirements of these regulations as applicable to MIT; and establishes a process for assigning an EHS Office staff member support and oversight responsibility to help ensure compliance with each requirement. Programs, Standard Operating Procedures (SOPs), Standard Operating Guidance (SOGs), and Fact Sheets are developed and distributed by the EHS Office for use in communicating requirements to the MIT community.

3.1.2 Communicating EHS Rules and Regulations to Affected Parties

Communicating EHS expectations and regulatory requirements to the MIT Community

MIT communicates EHS regulatory requirements and accepted best practices to affected faculty, researchers, staff, and students through a variety of means. The foundation of knowledge regarding regulatory requirements and MIT’s EHS standards and best practices is established through education and training, described in Section 4, Training of this Manual. It is important for new people to receive an orientation and to obtain EHS training before beginning work with or around potential hazards.

To support and reinforce training, and to communicate changes and best practice, the EHS Office develops and maintains an EHS Office Communications Plan (certificate login required). This plan helps to ensure development, proper targeting and systematic delivery of critical information regarding EHS matters. The plan identifies communication resources and tools available at MIT for use by EHS personnel.

A key resource for communicating EHS requirements and expectations at MIT is the EHS Office website. This website has content on a variety of topics and on services available for supporting EHS at MIT, and it includes access to written documents such as this manual, the Chemical Hygiene Template, the Hazard Communications Program, various SOPs/SOGs describing requirements and expectations related to EHS regulations and their implementation at MIT. The EHS website is the primary portal for sharing EHS information with the MIT community.

Communication is fostered by the EHS organizational structure described in Section 2, Roles and Responsibilities. Within this structure, information is transmitted from the EHS Office via the EHS Office Lead Contacts and DLC EHS Team members to the affected departments through the DLC’s EHS Coordinators. Information is exchanged using a variety of mechanisms, including e-mail and written communications, quarterly EHS Coordinators meetings, periodic DLC EHS Committee meetings, and direct communications between EHS Coordinators and EHS Office Lead Contacts. EHS Coordinators are the primary points of contact to distribute and communicate information throughout their DLC.

MIT’s EHS standards and regulatory requirements are also communicated directly to affected parties through training, inspections, and audits. Education and training, addressed in Section 4, Training of this Manual, is an integral component of the EHS Management System and is a significant tool for introducing and reinforcing MIT’s regulatory requirements and MIT compliance programs to individual faculty, researchers, staff, and students.

Inspections and audits, discussed in Section 6, Inspections and Audits of this Manual, further serve to communicate and reinforce regulatory requirements that are applicable to each laboratory or facility space. As each PI/ Supervisor registers space under his or her supervision in a central database and completes a hazard assessment, MIT’s standards and regulatory requirements that apply to each space are identified. The inspections and audits then help to ensure that the appropriate requirements are being met.

To facilitate communication regarding EHS matters, the EHS Office has established one phone number that can be used by MIT community members to reach any member of the office for urgent and non-urgent EHS matters, and the Office also has an e-mail address, environment@mit.edu, that can be used for questions about non-urgent matters or as a tool for the campus community to provide suggestions or express concerns.

More details regarding EHS Communications at MIT can be found in Section 8 of this manual.

MIT’s EHS standards and expectations are communicated to contract service providers at the time of engagement through the use of the Environment, Health and Safety Guidelines for Construction, Service and Maintenance Contractors (certificate login required) The EHS Office works with the Department of Facilities to ensure guidelines are communicated to contractors hired by the Department of Facilities and with EHS Coordinators and Facilities Managers for contractors hired directly by DLCs.

Communicating with Regulatory Agencies

MIT, as a complex, diverse organization, must communicate with a multitude of federal, state, and local regulatory agencies on a wide variety of topics and issues.

Any communications with regulatory or law enforcement agencies that concern environment, health and safety issues, or impact the whole Institute, including MIT policy, legal requirements, regulatory compliance, or the Institute’s EHS performance, must be coordinated through the EHS Headquarters Office (EHO) and the EHS Office. These procedures are described more fully in an internal document.

Communications with regulatory agencies that are of a routine nature, such as those that occur as a normal part of the Institute operations, and neither precedent-setting nor impact Institute-wide policies or issues, typically are conducted directly by employees with the relevant regulatory agency personnel.

There are regularly scheduled or unannounced visits by regulatory agencies to MIT and for those the EHS Office has developed an internal SOP for Regulatory Agency Visits (certificate login required). The SOP describes procedures for communications with federal, state, and local agencies, such as Environmental Protection Agency, Occupational Safety and Health Administration, Nuclear Regulatory Commission, Department of Environmental Protection, Department of Public Health, Cambridge Fire Department, and Cambridge Inspectional Services.

The PI/Space Registration Process (certificate login required) is the primary point of entry into the EHS Management System for faculty and supervisors, and their associated use of potentially hazardous and/or regulated materials and/or equipment. This Process is the fundamental building block upon which the major system components of hazard / regulatory identification and assessments, training, inspections, inventory, and emergency preparedness are based. The PI/Space Registration database is renewed as needed, but at least annually, when space or work with regulated materials and/or equipment changes occur.

The registration process creates an entry in the PI/Space Registration database for each laboratory or other facility space and associates with that space the names of the PI or Supervisor (PI/Supervisor) and the EHS Representative, a description of the type of space (lab, storage, etc.), emergency contact information, and the core hazard/regulatory types found in that space, such as chemicals, biological materials, ionizing radiation sources, non-ionizing radiation sources, flammable liquids, highly reactive materials, and large oil volumes. The emergency contact information cards, called “Green Cards,” are generated from the information contained in the PI/Space Registration database.

A hazard assessment is often completed simultaneously with the PI/Space Registration process and results in the Potential Hazards Inventory for the laboratory or work area. The Potential Hazards Assessment SOP (certificate login required) describes how to complete the Potential Hazards Assessment associated with PI/Space Registration.

During the Potential Hazards Assessment process, the DLC EHS Coordinator and the EHS Office Lead Contact evaluate the space and activities conducted in that space to more specifically identify the various hazard types and safety equipment contained within. This process is grouped into seven categories (Chemicals – General or Specific, Chemical Wastes, Biological, Radiation Sources, Non-ionizing Radiation Sources, General & Lab Safety, and Safety Equipment) to determine where potential hazards/regulations are present in, or applicable to, the space. The information from this process assists the EHS Office in developing and implementing appropriate programs for periodic assessments and control of hazards, training, inspections, and prevention activities.

In addition to the Potential Hazards Assessment process, the EHS Office coordinates the annual chemical reporting that satisfies the requirements of Environmental Protection Agency (EPA) mandated SARA Title III inventory and “Chemical of Interest (COI)” survey for the Department of Homeland Security (DHS). DLCs are required to keep a chemical inventory within their spaces including solvents and gases.

There are other specific EHS programs that identify the potential hazards and / or regulatory requirements associated with the research, study, or work activities conducted at MIT. Depending on the potential hazard, associated activities, and applicable regulations, these programs may require recording, reporting, authorizing, and / or registering the use of potential hazards or equipment, and completing required training. A list of some of these potential hazards or activities addressed by EHS programs includes, but is not limited to, the following:

- Use of radioactive materials

- Use of radiation producing machines

- Use of non-ionizing sources such as lasers, magnets, and RF systems

- Operations or activities producing greenhouse gas

- Use of explosives

- Use of biological agents and select agents

- Use and management of chemical inventory

For more detailed information on potential hazards, refer to each topic menu on the EHS website.

Regulatory Activities and Materials Assessment and Control

The Potential Hazards Inventory is used by the DLC in coordination with the EHS Office as a starting point for identifying where hazard/regulatory assessments may be needed. Hazard/regulatory assessments are performed to determine what controls are needed to reduce, eliminate or mitigate a hazard, and comply with regulatory requirements. Hazard/regulatory controls are addressed in Section 5.1, Hazard Assessment and Control.

EHS Coordinators make initial hazard/regulatory assessments using guidance provided by the EHS Office. The EHS Office Lead Contact and/or DLC EHS Team assist the EHS Coordinator as necessary, and generally take primary responsibility for more complex hazard/regulatory assessments. If the assessment determines that controls are needed to reduce or eliminate the hazard or to meet MIT’s EHS standards and/or regulatory requirements, recommendations are made to the appropriate parties, such as the DLC EHS Coordinator, PI/Supervisor, and/or Department of Facilities to address the hazards and requirements.

3.4.1 Standard Operating Procedure (SOP) Assessment

In some cases, a hazard assessment may determine that a Standard Operating Procedure (SOP) is needed to prevent potential regulatory violations or EHS incidents. The process of determining when it is necessary to prepare an SOP, Standard Operating Guideline (SOG) and/or fact sheet is documented in an SOP, Writing, Approving and Updating SOPs, SOGs and other Documents (certificate login required).

The standard format and a list of EHS-related SOPs, SOGs and other documents are available online.

3.4.2 Monitoring and Measurement

MIT conducts a variety of monitoring and measurement activities of workplace conditions to sustain compliance, protect student, staff, employee, and community health and safety, and to safeguard the environment. Because monitoring is often conducted to measure exposure to a hazard, monitoring and measurement activities are an important part of the hazard assessment process. Different groups at MIT perform monitoring and measurement activities, as described below.

3.4.2.1 Department of Facilities

The Department of Facilities conducts or oversees monitoring performed to assure compliance with some EHS regulations that relate to facilities operations such as

- wastewater testing to demonstrate compliance with the terms of MIT’s MWRA permit;

- monitoring required to comply with MIT’s Title V air emissions permit, including continuous stack testing conducted at the Central Utility Plant;

- keeping records of the gallons of paint used at the paint booth;

- checking secondary containment areas at above ground oil storage tanks;

- monthly testing of emergency generators;

- tracking of on-site emergency generator operations by recording operating time or gallons of fuel used, depending on the generator;

- tracking refrigerant usage for chiller systems;

- annual inspections of deluge showers, and

- annual inspections of portable fire extinguishers.

3.4.2.2 Division of Student Life

The Division of Student Life conducts or oversees monitoring performed to ensure compliance with some EHS regulations as well as ensuring safety to the MIT community by:

- measuring carbon dioxide emissions at the Johnson Ice Rink after Zamboni use;

- assisting with sampling Zesiger Center Pool and Alumni Pool on a routine basis for fecal coliforms in order to meet Massachusetts regulations;

- reviewing and monitoring various student projects depending on the location of said project;

- evaluating Athletics events;

- examining Campus Activities Complex events;

- assessing Dining Services events; and

- arranging fire evacuation drills.

3.4.2.3 EHS Office

The technical Programs and service teams within the EHS Office conduct a wide variety of initiatives and programs that involve monitoring and measurements to sustain regulatory compliance, proactively assess risk to the MIT community, and support a culture of safety. Service Teams are comprised of members from each Program within the EHS Office and occasionally DLC members. These are described below:

- The Environmental Management Program (EMP) conducts services and activities to ensure that air emissions, wastewater discharges and chemical waste generated from MIT are protective of the environment and compliant with all environmental regulations. EMP provides environmental oversight, advice, consultation training as well as direct operational services for environmental permitting, environmental data reporting, and responses to release / potential release of hazardous materials to the environment. EMP collects and manages all chemical hazardous waste generated at the Institute and gathers data on the types and quantities of chemical hazardous waste generated, which is filed biennially with the applicable regulatory agencies. EMP also compiles Greenhouse Gas (GHG) inventory for campus, collects commuting information for MIT staff and students for the annual Rideshare report to the Massachusetts Department of Environmental Protection (DEP); and gathers inventory data on certain chemicals to prepare the SARA Title III submittal required by the EPCRA regulations and to comply with Department of Homeland Security (DHS) Chemical Facility Anti-Terrorism Standards (CFATS) program.

- The Occupational and Construction Safety Program (OCSP) monitors OSHA-defined confined spaces to determine if they are safe for entry by workers. The OCSP also conducts project evaluations for the Hot Work Permit Program, which may include a monitoring component. The OCSP also evaluates work areas for many traditional industrial safety issues such as emergency egress, Machine/Woodworking Shop Safety, Powered Industrial Trucks, Flammable Liquids/Gases/Solids, Portable Extinguishers, Building Inspections, Confined Space Entry, Fall Protection, Mobile Elevated Work Platforms, Student Projects/Events, Construction Safety, Explosives, Injury Reporting, Lock Out/Tag Out, Electrical Safety, Lab Decommissioning Operations/ Planning, Personal Protective Equipment, Pressure Vessels, Emergency Preparedness Planning , Emergency Showers/Eyewashes, Special Events, Projects Involving Minors, Compressed Gases, Cryogenic Liquids, Campus Fire Safety, Lab and Facility Design, Life Safety/Fire Protection Systems, Walking/Working Surfaces, Vehicular Safety, Explosives Safety, Hoisting Equipment, Job Hazard Analysis.

- The Industrial Hygiene Program (IHP) oversees programs related to evaluating and controlling exposures to hazardous chemicals, ergonomics, noise and heat. IHP oversees Institute’s compliance for related OSHA regulations, including Chemical Hygiene Plan, Hazard Communications Plan, Respiratory Protection Plan, and OSHA permissible exposure limits. IHP also manages laboratory fume hood and workplace ventilation programs. IHP provides guidance to MIT on laboratory, HVAC design and other industrial hygiene related controls.

- The Radiation Protection Program (RPP) has extensive ionizing radiation protection monitoring programs to assure compliance with applicable regulations and MIT’s licenses for storage and use of radioactive materials. These programs include risk assessment for radioactive use protocols, training, program development and compliance, routine testing of laboratory surfaces for contamination, radiation worker monitoring of external dose through the use of dosimeters, potential internal dose through bioassay and whole body scans, effluent concentrations for volatile radionuclides, and environmental monitoring at designated local and perimeter sites. RPP collects and manages all radioactive waste generated at the Institute and files an annual report on the quantities and types with the applicable regulatory agencies. They also collect biosharps and biological waste through the Regulated Medical Waste program. RPP registers all radiation producing equipment including analytical, veterinary and medicinal X-Ray machines, and particle accelerators in accordance with the required state regulations. In addition, RPP has non-ionizing radiation monitoring programs that include registration and risk assessment associated with the use of class 3b and class 4 lasers, analytical magnets and MRI units, and RF sources including radar, microwaves, and telecommunications.

- The Biosafety Program (BSP) oversees a monitoring program for biological research that tracks the use of recombinant DNA (rDNA), biological toxins, microbial pathogens, human materials, associated safety training and occupational health topics. Reported incidents, accidents, and exposures involving biological materials are closely tracked in order to identify trends and improve risk assessment. BSP also monitors autoclave validation and calibration to assure adequate function and for sterilizing biological waste, research and/or medical materials and equipment. This monitoring program is in place to maintain safety, regulatory, and accreditation criteria compliance. The purchase and receipt of regulated or more highly hazardous materials pertaining to biological research (e.g. select toxins and DEA Controlled Substances) are monitored by BSP in collaboration with MIT Sourcing & Procurement. BSP also monitors specific environments for biological contaminates. For instance, BSP conducts water quality monitoring of the Institute’s swimming facilities on a routine basis in collaboration with the Division of Student Life. BSP also measures airborne mold levels as part of indoor air quality investigations. As requested, BSP staff will monitor for microbes on surfaces or in the air as a part of epidemiological investigations.

- Organization Service Team provides oversight to assure EHS-MS governance framework is implemented and maintained and facilitates the DLC EHS Coordinator and EHS Lead Contact relationship through periodic meetings and communications. This team also oversees the PI/Space Registration process and provides advice and direction regarding professional development needs of the EHS Office staff and EHS Coordinators.

- Inspection/Audit Team provides oversight to implementation and maintenance of the inspection and audit program. The team monitors inspection data from Level II inspections to identify trends and leading indicators of EHS concern.

- Training Service Team provides oversight for all EHS training needs, assists in the development of new EHS training courses, aids in the development and update of the EHS Training Needs, and tracks the maintenance of the database used for managing official training records.

- Emergency Preparedness and Response Service Team provides oversight for the 24-hour emergency response services provided by the EHS Office, the coordination of the EHS responses with MIT’s Emergency Response Group, and manages the emergency response follow-up process.

- Laboratory and Facility Design and Construction Review Services Team formally collaborates with the Department of Facilities and DLCs to assure that EHS requirements and concerns are addressed systematically in new construction and renovation projects at MIT.

- Technology Service Team has oversight for the development and maintenance of the technology needed to support EHS activities, including EHS web resources, the EHS Office intranet, and all databases associated with the EHS-MS.

- Communications Service Team (CST) works to promote effective and timely communication among all the EHS stakeholders across the Institute and MIT community to improve EHS performance. More details about the CST are in Section 8.2 of this manual

- Regulated Waste Service Team coordinates activities related to chemical, biological, radiological and universal waste at the Institute. It provides oversight of compliance issues and identifies and recommends opportunities for continuous improvement and waste reduction.

- The Hazardous Materials Shipping Team (HMST) provides support and services to the campus community to help assure that hazardous materials and dangerous goods are shipped from MIT in accordance with regulatory requirements by personnel trained to do such shipments. The shipping service provided by the team includes guidance on shipping requirements, packaging, labeling, and document preparation. The team also provides some shipping training and ensures proper management of training and shipping records.

- Safe and Sustainable Labs Team utilizes the EHS-MS to strengthen and introduce sustainable initiatives to campus, to communicate updates on sustainable projects and opportunities, and to identify new areas of improvement, specifically as they apply to EHS. Examples include lab recycling, fume hood energy management, lab sustainability assessment and chemical sharing opportunities with the EHS Office.

3.4.3 Engineering Controls

When the hazard assessment process indicates a potential EHS regulatory impact, an evaluation to implement engineering controls to prevent or reduce workplace exposures or minimize compliance issues is conducted. These controls are designed to be part of the space (for new spaces) or retrofit (for existing spaces). Examples of engineering controls include: fume hoods, biological safety cabinets, glove boxes, secondary containment for tanks and containers, neutralization systems for wastewater discharges, air cleaning systems, and others. These controls are typically implemented or overseen by the Department of Facilities, the EHS Office, or both, in conjunction with external consultants and/or contractors.

MIT has an Emergency Response System that follows the National Incident Management System (NIMS) Protocol, responds to all emergencies and incidents on campus, and is integrated into MIT’s response system and the overall structure and culture of the MIT community. A key component of this program is the Emergency Operations Plan.

The EHS Office provides full-time, around-the-clock emergency response support and service to the MIT community. Emergency EHS services can be obtained by calling the EHS Office at 617-452-3477 (2-EHSS) during business hours or by dialing 617-253-4948 or x100 off hours. The EHS emergency response system consists of a rotating weekly five person roster made up of an individual from each of the five EHS Programs: Biosafety, Environmental Management, Industrial Hygiene, Radiation Protection, and Safety Programs. One person is assigned to be the Primary contact with the others providing support as needed. Refer to the MIT EHS Response System SOP (certificate login required). New employees are provided training and introduced into the system when approved by their Associate Director. Annual refresher training is provided to members of the EHS Response System that consists of reviewing current and introducing new protocols, and discussing response issues to identify areas for improvement.

MIT’s EHS Office has developed standard procedures for responding to spills of hazardous materials. The Spill Response Procedures SOP (certificate login required) provides guidance on how to differentiate between minor and major spills and clarifies response procedures for each type of spill. Major spills or releases require immediate notification to the MIT Police or the MIT Operations Center, or both, who are then required to contact the EHS Office and/or the Cambridge Fire Department. The appropriate EHS on-call Program representative will determine whether external reporting is necessary.

MIT has a robust agenda of positive environmental initiatives to make our campus more sustainable and to reduce pollution. A pollution prevention program is an integral part of MIT’s commitment to excellence in environment, health, and safety stewardship on our campus. To this end, the Institute adopts and implements policies and practices that reduce or eliminate the use of hazardous materials and the generation of waste streams (both hazardous and non-hazardous) whenever possible.

The EHS Office actively collaborates with the MIT Office of Sustainability, the Department of Facilities, other DLCs and student groups to reduce the volume and toxicity of the Institute’s waste streams. Leveraging MIT’s collaborative culture around the following goals frame MIT’s Pollution Prevention efforts:

- Conserve resources (water and energy), seeking planned reductions in MIT’s consumption;

- Reduce campus air emissions, including those from transportation, of greenhouse gases and regulated pollutants;

- Increase the recycling and conservation of materials;

- Reduce material and resource consumption including office and laboratory supplies;

- Increase the use of environmentally friendly products and materials;

- Reduce the volume and toxicity of our waste streams;

- Inform our students, faculty and staff in sustainable concepts so that they may apply them in their professions;

- Support community-wide and regional sustainability efforts; and

- Establish procedures and targets for implementing sustainable design principles in new and renovated projects.

See also MIT Office of Sustainability Reports.

MIT’s EHS Policy describes and communicates the Institute’s commitment to excellence in environment, health, and safety stewardship. Consistent with this objective, the Institute directly considers and seeks to mitigate the EHS impacts of its operations by integrating EHS criteria into its planning and decision-making processes.

The EHS Office/EHS Headquarters Office (EHO), through the Managing Director for EHS Programs, participates in Institute-wide EHS planning and policy-making, and together with the Institute Council on EHS is responsible for overseeing overall EHS policy implementation, including regulatory compliance, and EHS initiatives. Members of the EHO and EHS Office conduct internal management review of the EHS Management System. In addition, the EHO is responsible for developing, implementing, and managing the vision, strategic direction, and oversight of the EHS Office. The creation of a high-level EHO, overseen by a senior administrator reporting directly to the Executive Vice President and Treasurer, with dotted line reporting to Provost, and Chancellor, demonstrates the Institute’s commitment to environmental stewardship and compliance. This organizational structure effectively leverages MIT’s resources to have lasting, Institute-wide impact, and is consistent with the objectives set out in the EHS Policy.

Further integration of EHS issues into MIT planning, decision-making, and operations is achieved through the use of specialized EHS Councils and Committees as outlined in Section 2, Roles and Responsibilities of this Manual.

EHS considerations are integrated into Institute-wide operations at two levels. One level addresses existing physical spaces or buildings, and operations; the other addresses new or modified buildings and operations.

Existing Buildings and Operations

The process for ensuring that EHS requirements are integrated into existing buildings and operations involves several linked components. These include EHS training; PI/Space registration; hazard/regulatory identification, assessment, and control; incident and non-compliance investigations; inspections and audits; Emergency Preparedness and Planning; and the EHS Office communications activities.

Through the corrective action process, EHS issues are identified, communicated, tracked, and resolved. This integrated and on-going process allows for identifying and acting upon opportunities for continual improvement of EHS performance. When a potential problem or opportunity for improvement is identified, the EHS Office conducts an investigation resulting in a communication or report to the DLC with findings and recommendations.

New and Modified Buildings and Operations

EHS requirements and considerations are integrated into the planning, design, and construction of new and renovated buildings and operations through the Laboratory and Facility Design and Construction Review Process. For new spaces (including new construction, renovations, and space changes), the EHS Office works closely as a member of the design and construction project team with the Department of Facilities, the client DLC, and external designers and construction firms. EHS Office participation on the project team is through the auspices of the EHS Laboratory and Facility Design and Construction Review Services. Once a project is identified, the team leader assembles an EHS Project Review Team and assigns an EHS Project Liaison and EHS Construction Liaison.

The EHS Laboratory and Facility Design and Construction Review Services Team leader provides direction and oversight to the review process and to the EHS Office Construction Safety Program, works with the overall Project Manager to resolve issues and report significant impacts to MIT management, and coordinates the transfer of EHS responsibilities to the EHS Office Lead Contact and DLC EHS Coordinator following building commission and occupancy.

Taking MIT’s EHS Policy to a greater level of specificity, Institute-wide EHS objectives are established in the MIT EHS Policy, and focus on EHS stewardship, sustainability, compliance, accountability, opportunity, and performance. The EHS Policy is reviewed periodically and modified, as needed, by the Institute Council on Environment, Health and Safety and approved by the Academic Council of MIT, if required.

The EHS Headquarters Office (EHO) sets vision and high-level environment, health and safety objectives and goals for the central administration of MIT and brings Institute-wide goals and objectives to respective Institute Committees for endorsement.

In addition, if systemic compliance problems are identified within any DLC or contractor operations, the EHS Management Systems requires the development of an action plan to address the problem. The action plan must include steps to be taken to investigate and remedy the problem, including tracking and reporting status. The EHS Office and DLC EHS Coordinators and Committees monitor the implementation and effectiveness of these additional action plans.

MIT personnel who participate in, or oversee activities that are regulated because of potential risks to the environment, health, or safety must receive training appropriate to this regulated activity. This training must be completed prior to beginning the regulated activity. In some cases, work can be done under the direct supervision of a qualified person until training is completed.

Refresher training, also called retraining, may be required periodically if the trainee is engaged in specific activities. The EHS Office and DLC EHS Coordinators track the required training and retraining, and MIT personnel are informed when their retraining is due. The EHS Training Needs pairs regulated activities to training requirements. An expiration date is listed for those trainings where refresher training is required.

Individuals who intend to engage in EHS-regulated activity at MIT must determine their training requirements via the web-based EHS Training Needs (certificate login required). This includes MIT faculty, employees, researchers, students, and visiting scientists. The Department of Facilities, Division of Student Life, Division of Comparative Medicine, and EHS Office and other administrative units use training groups to administer training requirements for employees instead of having them complete the online EHS Training Needs.

The EHS Training Needs (certificate login required) is a web-based tool used by MIT to identify individuals engaged in regulated activities, to assess the types and levels of EHS risks they may encounter and regulations that apply to their activities, and to create and track a customized training program for each individual. The assessment creates and tracks individual training programs based on different criteria such as departmental or EHS activity or job title. Twice a year, EHS Representatives in laboratories or other work areas are notified to review the list of trainees affiliated with the lab or work area and to update the list using the online Training Reconciliation. If a trainee is added, the system sends that person an email and a link to update their activity selection.

4.1.1 EHS Training Needs by Activity

- A trainee is initially informed about EHS training requirements, and the need to complete them before beginning work with hazardous materials, by his or her Principal Investigator (PI)/Supervisor, DLC EHS Coordinator, or EHS Representative.

- A trainee is then instructed to register through the Atlas Learning Center and to create an EHS Profile to determine their EHS Training Requirements. The trainee is prompted through a series of questions to identify the specific activities that they will be engaged in. By identifying specific regulated activities, the EHS Training Needs is able to identify required training courses for individual trainees. The results of the EHS Training Needs are saved in the Atlas Learning Center.

- A trainee must complete the EHS Training Requirements before beginning work, or be under the direct supervision of a qualified person until training is completed.

- A trainee must update their EHS Training Needs if the trainee’s regulated activities change or they move to a new laboratory, facility, or DLC.

- Training reminder e-mails are sent 30 days after the profile is completed, 30 days and 7 days before the retraining is due, and 7 days after the training expiration.

The DLC EHS Coordinator may assist a PI in completing the EHS Training Needs.

4.1.2 EHS Training Needs by Job Title or Function

The training system also supports the creation of a customized EHS training program based on an individual’s job title or function. This approach is most appropriate where training requirements are the same for all those with the same job title or function. This rule is administered by the Atlas Learning Center based on the specifications of the EHS Office and DLC EHS Coordinators.

4.1.3 EHS Training Needs for Academic Courses

The training system has the ability to link training requirements to students registered in an undergraduate/graduate academic lab course. This capability provides instructors with the ability to monitor and run reports on the group of students enrolled in their courses. EHS Office personnel and/or DLC EHS Coordinator work with instructors to determine which EHS training modules are required for their courses. The training rules are then added to the Atlas Learning Center so that, when students who are registered for that course go to the Learning Center, the requirements are listed automatically without the need for completing the EHS Training Needs.

4.1.4 EHS Training Needs by Training Groups

Training groups can be used when an identified group requires a specific set of training requirements. This is used if none of the other methods for determining EHS training requirements as listed above are appropriate.

Other DLCS may make use of this feature to delineate comprehensive EHS training requirements for their staff by groups.

- The DLC EHS Coordinator with EHS Office support creates an EHS curriculum and training program for group where EHS training is needed. These training programs are then uploaded into the Atlas Learning Center, a central repository for all training.

- The training and/or retraining is then scheduled and completed before regulated activities begin.

4.1.5 EHS Training Needs Identification at Lincoln Lab

All Lincoln Laboratory employees are required to complete an annual Training Needs Identification questionnaire (Activity Selection) to determine their training needs. Some non-research Lincoln employees that can be identified by an HR-driven attribute (organizational assignment, staff category, job) are exempt from the activity selection requirement because their training needs can be identified and assigned based on this attribute (i.e., plumber, carpenter, security officer, etc.).

There are certain regulated activities that require a participating individual to have specific training before engaging in that regulated activity. Certain training may be recommended as a best practice when there is no specific regulatory requirement. Completing a recommended course results in a training completion record, but does not trigger retraining requirements or factor into training compliance metrics. Refer to list of regulated activities for a complete list.

In addition to providing the regulatory-driven required EHS training, MIT’s goal is to promote good practices to advance overall excellence in the workplace and learning environment. To this end, the Institute actively promotes training and awareness in elective practices that support implementation of the EHS Management System, the Institute’s EHS policy, and MIT’s goals for a sustainable campus.

MIT EHS Office has developed training and materials to inform PI’s about their EHS responsibilities, EHS policies, and suggested best practices for developing a strong safety culture within their lab group.

MIT has several mechanisms through which EHS training can be delivered, including traditional classroom based training, virtual training, web-based training, or blended learning involving both classroom and web-based training components. The course content is consistent for each course regardless of the method of completion.

4.4.1 Web-based Training

If a web-based training course is available and allowed by their DLC(s), the trainees can launch the course after completing their EHS Training Needs (certificate login required) directly via the Atlas Learning Center. When the web-based training course is successfully completed, the results of the training are automatically captured in the Atlas Learning Center. EHS web-based training modules include the contact information for the EHS Office so that students completing web-based training can contact EHS if they have questions during the training.

4.4.2 EHS Office and DLC Classroom Training

After completing their EHS Training Needs (certificate login required), the trainees can enroll in scheduled classroom-based training courses offered by both the EHS Office and specific DLCs. The content for these classes is broadly applicable throughout DLCs and is consistent with the web-based training, but the course is delivered in a classroom format where the trainee can interact directly with the instructor. The instructor is responsible for submitting training attendance documentation to the EHS or DLC Training Registrar for uploading to the Atlas Learning Center.

4.4.3 Laboratory/Workplace-Specific Training

Laboratory and/or workplace-targeted EHS training is provided directly by the PI/Supervisor, EHS Representative or other designated individual to meet these specialized training needs and requirements. The DLC EHS Coordinator submits the training attendance documentation to the EHS Office for upload to the Atlas Learning Center.

Information captured by the Institute’s Learning Center system includes, but is not limited to:

- trainee MIT ID number and Kerberos username;

- the DLC(s) and PI(s)/Supervisor(s) for which the trainee works or studies;

- the first and most recent date that the EHS Training Needs was completed;

- the training requirements determined by the training needs;

- required completion dates for each course; and expiration dates of the initial training if retraining is required.

All Lincoln employee training completion records and activity selection information is maintained in the Lincoln Laboratory SAP Learning Management System (LMS.)

4.5.1 Access to Training Records

MIT uses a central ‘roles’ database to administer authorizations for access to secure information across the Institute. For the Atlas Learning Center, DLC Heads/Directors, DLC EHS Coordinators, EHS Coordinator administrative designees, and DLC PIs/Supervisors, each have roles recognized by the system that enable them to access training information for their specific DLC. EHS Office Lead Contacts have access to the entire training records database. To ensure proper controls, DLC Heads/Directors, PIs/Supervisors, and EHS Representatives are not granted permission to update training records in the Atlas Learning Center. Some DLC EHS Coordinators and their administrative designees are granted permission to update records for their DLCs.

4.5.2 Standard Training Reports

The ability to generate specific reports on training status is available via the Atlas Learning Center. Authorized DLC personnel can access training status information through a set of standard reports that include: reports about trainee required courses, courses that have not been completed, and courses that have been completed. These standard reports have been designed based on the needs and inputs of the following data users: EHS Representatives, PIs/Supervisors, DLC EHS Coordinators, EHS Office Lead Contacts, and other EHS Office personnel. DLC personnel can submit requests for additional types of training reports to their DLC EHS Coordinator and/or EHS Office Lead Contact, who will then queue the request for future system development.

4.5.3 Archiving Training Information

Trainee data generated by the EHS training program is routinely archived to ensure a robust and accurate data set. The periodicity of archiving is determined by the EHS Office to foster accurate information and, to the extent feasible, takes into consideration the annual academic year cycles for students and staff appointments and the need for regular archiving of inactive students, staff, and employees from the system. EHS training records are archived according to regulatory requirements or MIT determined best practice.

4.5.4 Training Reconciliation