Decontamination and Decommissioning of Spaces

Before demolition can begin, Project Managers need to ensure that project spaces have been cleared of all potentially hazardous materials. This process varies in its scope, and is dependent on factors such as:

- Type of space – office, corridor, lab, mechanical

- Size of project – repair, small-scale, large-scale, tear-down

- Age of space – old building, recent renovations, newer building

- Items in the space – abandoned equipment, lab hoods, fluorescent lighting, chemicals, paint

At the PM’s request, the EHS Project Liaison can coordinate with the EHS Environmental Management Program to ensure that spaces have been abated for hazardous materials; and that equipment has been properly decontaminated and decommissioned before beginning demolition.

At the PM’s request, the EHS Project Liaison can coordinate with the EHS Environmental Management Program to ensure that spaces have been abated for hazardous materials; and that equipment has been properly decontaminated and decommissioned before beginning demolition.

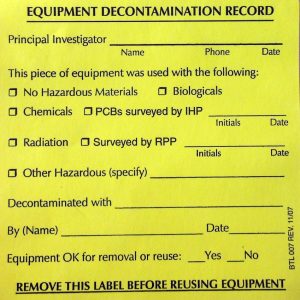

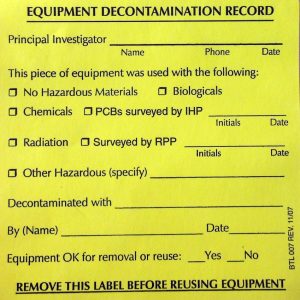

Laboratory and research spaces require particular attention. Abandoned equipment and instrumentation must be tagged with a lime green “MIT Equipment Decontamination Record” sticker before they can be removed. The decontamination process for equipment and instrumentation depends on how it was used, and the possible contaminants. The Project Liaison will coordinate with the appropriate EHS Team to advise the Project Manager on the necessary procedures. Potential contaminants include radioactive materials, chemicals, biological or biohazardous agents, PCB’s.

Hazardous Materials

Construction materials that contain hazardous compounds are a concern even for small projects, as well as projects in new or recently renovated spaces. The testing for the presence of hazardous materials is best done early in the project, in this way, any required remediation can be accounted for during the initial planning. Project Managers can arrange for testing through their Project Liaisons, or can contact the appropriate EHS Officers.

Asbestos is the most commonly found hazardous material in construction projects on campus. A few of the other hazardous materials that PM’s should be aware of are lead, PCB’s, mercury, and potentially contaminated soil. Universal waste items like light bulbs, ballasts, and batteries also need to be properly managed.

Listed below is basic information on some of the hazardous materials you might encounter in your projects. For additional information, or if you have questions about other potentially hazardous materials in your particular site, please contact your Project Liaison or Construction Safety Liaison.

Asbestos

If you plan to do a renovation or a demolition at the Institute, call the Industrial Hygiene Program (IHP) in the Environment, Health, and Safety Office at (617) 452-3477. Someone from the Asbestos Program will help you.

Common locations where asbestos may be found include pipe insulation (with all fittings included), floor tiles, ceiling tiles, gasket materials, fire door fill, panels in cooling towers, and boiler insulation. Asbestos is integrated in over three thousand products and can still be purchased over the counter today.

All asbestos abatement at MIT is performed by outside vendors. These vendors are licensed asbestos abatement contractors. Asbestos signs and work areas are indications of ongoing abatement activities. There is an asbestos warning sign at the entrance to the abatement work area. Every abatement activity at MIT is monitored by IHP or an outside environmental consultant who contracts with IHP.

Do not enter abatement areas when this sign is posted.

- Lead

- PCBs

- Mercury

- Soils and groundwater

Managing Construction Waste

PLs and CSLs can provide guidance to Project Managers in managing waste generated by demolition and construction of their projects.

General contractors should submit a Draft Waste Management Plan to the Project Manager. Copies of invoices and bills of lading should be forwarded to EHS for their records.

MIT requires that, as a minimum, the following materials must be recycled:

- Corrugated Cardboard

- Clean dimensional wood

- Uncoated asphalt, bricks, and concrete (ABC)

- Metals including stud trim, ductwork, piping, reinforcing steel (rebar), roofing, steel, iron, galvanized sheet steel, stainless steel, aluminum, copper, zinc, lead, brass, and bronze

- Any other materials for which reuse, salvaging, or recycling results in a net cost that is equivalent to or less costly than landfill disposal or incineration

Integrated Pest Management (IPM) During Demolition and Construction

Pest activity on project sites can be a problem. Occupants of neighboring buildings or areas should be notified prior to beginning work that there is a potential for increased pest activity. If Project Managers or contractors become aware of pest issues on their project site they can communicate directly with MIT’s contracted pest control provider (EHS Pest Control Services) through the Atlas website.

Some considerations toward minimizing pest problems during demolition and construction:

- Demolition debris should be removed from the site as quickly as feasible or possible

- Appropriate rodent control actions must be taken along the perimeter and surrounding areas of construction sites

- At grade access points on the perimeter of project areas to neighboring spaces should be sealed and door sweeps installed wherever possible

- Worksites should remain “broom clean” and all waste generated removed daily, particularly food waste generated from coffee or lunch breaks, to prevent harborage and food sources

For information on incorporating IPM into the design of your project spaces, including kitchens, building interiors and exteriors, contact your PL or CSL.

Decontamination and Decommissioning of Spaces

Before demolition can begin, Project Managers need to ensure that project spaces have been cleared of all potentially hazardous materials. This process varies in its scope, and is dependent on factors such as:

- Type of space – office, corridor, lab, mechanical

- Size of project – repair, small-scale, large-scale, tear-down

- Age of space – old building, recent renovations, newer building

- Items in the space – abandoned equipment, lab hoods, fluorescent lighting, chemicals, paint

At the PM’s request, the EHS Project Liaison can coordinate with the EHS Environmental Management Program to ensure that spaces have been abated for hazardous materials; and that equipment has been properly decontaminated and decommissioned before beginning demolition.

At the PM’s request, the EHS Project Liaison can coordinate with the EHS Environmental Management Program to ensure that spaces have been abated for hazardous materials; and that equipment has been properly decontaminated and decommissioned before beginning demolition.

Laboratory and research spaces require particular attention. Abandoned equipment and instrumentation must be tagged with a lime green “MIT Equipment Decontamination Record” sticker before they can be removed. The decontamination process for equipment and instrumentation depends on how it was used, and the possible contaminants. The Project Liaison will coordinate with the appropriate EHS Team to advise the Project Manager on the necessary procedures. Potential contaminants include radioactive materials, chemicals, biological or biohazardous agents, PCB’s.

Hazardous Materials

Construction materials that contain hazardous compounds are a concern even for small projects, as well as projects in new or recently renovated spaces. The testing for the presence of hazardous materials is best done early in the project, in this way, any required remediation can be accounted for during the initial planning. Project Managers can arrange for testing through their Project Liaisons, or can contact the appropriate EHS Officers.

Asbestos is the most commonly found hazardous material in construction projects on campus. A few of the other hazardous materials that PM’s should be aware of are lead, PCB’s, mercury, and potentially contaminated soil. Universal waste items like light bulbs, ballasts, and batteries also need to be properly managed.

Listed below is basic information on some of the hazardous materials you might encounter in your projects. For additional information, or if you have questions about other potentially hazardous materials in your particular site, please contact your Project Liaison or Construction Safety Liaison.

Asbestos

If you plan to do a renovation or a demolition at the Institute, call the Industrial Hygiene Program (IHP) in the Environment, Health, and Safety Office at (617) 452-3477. Someone from the Asbestos Program will help you.

Common locations where asbestos may be found include pipe insulation (with all fittings included), floor tiles, ceiling tiles, gasket materials, fire door fill, panels in cooling towers, and boiler insulation. Asbestos is integrated in over three thousand products and can still be purchased over the counter today.

All asbestos abatement at MIT is performed by outside vendors. These vendors are licensed asbestos abatement contractors. Asbestos signs and work areas are indications of ongoing abatement activities. There is an asbestos warning sign at the entrance to the abatement work area. Every abatement activity at MIT is monitored by IHP or an outside environmental consultant who contracts with IHP.

Do not enter abatement areas when this sign is posted.

- Lead

- PCBs

- Mercury

- Soils and groundwater

Managing Construction Waste

PLs and CSLs can provide guidance to Project Managers in managing waste generated by demolition and construction of their projects.

General contractors should submit a Draft Waste Management Plan to the Project Manager. Copies of invoices and bills of lading should be forwarded to EHS for their records.

MIT requires that, as a minimum, the following materials must be recycled:

- Corrugated Cardboard

- Clean dimensional wood

- Uncoated asphalt, bricks, and concrete (ABC)

- Metals including stud trim, ductwork, piping, reinforcing steel (rebar), roofing, steel, iron, galvanized sheet steel, stainless steel, aluminum, copper, zinc, lead, brass, and bronze

- Any other materials for which reuse, salvaging, or recycling results in a net cost that is equivalent to or less costly than landfill disposal or incineration

Integrated Pest Management (IPM) During Demolition and Construction

Pest activity on project sites can be a problem. Occupants of neighboring buildings or areas should be notified prior to beginning work that there is a potential for increased pest activity. If Project Managers or contractors become aware of pest issues on their project site they can communicate directly with MIT’s contracted pest control provider (EHS Pest Control Services) through the Atlas website.

Some considerations toward minimizing pest problems during demolition and construction:

- Demolition debris should be removed from the site as quickly as feasible or possible

- Appropriate rodent control actions must be taken along the perimeter and surrounding areas of construction sites

- At grade access points on the perimeter of project areas to neighboring spaces should be sealed and door sweeps installed wherever possible

- Worksites should remain “broom clean” and all waste generated removed daily, particularly food waste generated from coffee or lunch breaks, to prevent harborage and food sources

For information on incorporating IPM into the design of your project spaces, including kitchens, building interiors and exteriors, contact your PL or CSL.